Ansys is a powerful engineering simulation software that can be used for various analysis tasks, and thermal analysis is one of its key capabilities.

Quick Tips and Tricks, Tutorials for Ansys , OpenFoam , OpenSource FEA and more

Tuesday, May 28, 2024

Tuesday, September 26, 2023

💥💥💥 How to avoid peak stresses in Structural Analysis in Ansys Workbench

Peak stresses in structural analysis are often caused by stress singularities, which are artificial stresses computed because of simplification in the FEA model. Some common causes of stress singularities are sharp corners, stiff boundary conditions, point loads, constraint equations, etc.¹

There are several ways to avoid or deal with peak stresses in Ansys Workbench, depending on the nature and purpose of the analysis. Some possible methods are:

- Submodeling: This involves creating a submodel at the high stress locations with enough detail (e.g. fillet radius) along with mesh convergence study. This is the most accurate and reliable method, but also the most time-consuming and complex.¹

- Stress Concentration Calculation: This involves using Roark's formulas for stress and strain or other analytical solutions to determine the appropriate factors relative to the nominal stress. This works well if the load pattern and geometry are close to the textbook cases. It serves as a good way to ballpark a similar type geometry.¹

- Hot Spot Method: This involves creating a path of stress to the singularity and extracting the stress value at a certain distance away from the singularity (e.g. 1 mm), where it is assumed the stresses are adequately far away. Often times a fudge-factor on top of the extracted stress value is applied to build in some conservative margin. This method takes some upfront homework, is quick and dirty and may require good hand waving skills.¹

- ERESX Command: This is a command that controls the extrapolation settings in Ansys. By using ERESX,NO, one can force Ansys to copy the integration point stresses to the nodes. This ensures that stresses will never exceed yield as the stresses at the integration points can never exceed yield.³

- Thermal-Stress Analysis: This is a type of analysis that accounts for the thermal strain due to temperature changes. This can affect the stress distribution and magnitude in the model. One can perform a thermal-stress analysis by sharing model data between thermal and structural using the same or dissimilar mesh.⁴

You can learn more about these methods by following the links in the references. I hope this helps you with your structural analysis. 😊

Source:

(1) FEA Stress Singularities - Ansys Tips. https://www.ansystips.com/2017/05/fea-stress-singularities.html.

(2) Elastic-Plastic Analysis in ANSYS Gives Stress Above Yield | Nick J .... https://medium.com/@nickjstevens/elastic-plastic-analysis-in-ansys-gives-stress-above-yield-nick-j-stevens-81d990f1a78.

(3) Performing a Thermal-Stress Analysis - ANSYS Innovation Courses. https://courses.ansys.com/index.php/courses/structural-boundary-conditions/lessons/performing-a-thermal-stress-analysis-lesson-6/.

(4) Ansys structural analysis tutorials - Pure bending stress analysis .... https://www.youtube.com/watch?v=8awQ2UYXIBA.

How to perform submodeling in Ansys Workbench?

Submodeling in Ansys Workbench is a technique that allows you to refine the stress analysis of a region of interest without having to mesh the whole model with fine elements. It involves creating a submodel of the area you want to focus on and applying the displacement (and temperature) results from the global model as boundary conditions on the submodel. This way, you can capture the effects of local features, design changes, or non-linearities in the submodel without affecting the overall response of the system.

To perform submodeling in Ansys Workbench, you can follow these general steps:

- Generate the solution on the global model using the Mechanical tool.

- Create the submodel geometry in a separate Mechanical window or in SpaceClaim. You can use a local coordinate system to define the submodel location and orientation.

- Attach the submodel to the engineering data and solution of the full model using the Model cell in the Project Schematic.

- Define a Remote Displacement boundary condition on the submodel and import the Cut Boundary Constraint from the full model solution. This will apply the displacement (and temperature) results from the full model to the submodel.

- Define the mesh size and any other settings for the submodel analysis. You can use Named Selections to control the mesh refinement in the submodel.

- Solve the submodel and review the results. You can compare the results with the full model or with analytical solutions to verify the accuracy of the submodeling technique.

You can find more details and examples of submodeling in Ansys Workbench by following the links in the references¹²³⁴⁵⁶⁷. I hope this helps you with your structural analysis. 😊

Source:

(1) Performing Submodeling in Ansys Mechanical — Lesson 6. https://www.youtube.com/watch?v=WC9bN2B9w2M.

(2) How to Use Submodeling in Ansys Mechanical | Ansys Tutorials. https://www.youtube.com/watch?v=LEU6LlGUPAI.

(3) Ansys Sub modeling. https://www.youtube.com/watch?v=_7girXRDK2w.

(4) Submodeling in ANSYS Mechanical: Easy, Efficient, and Accurate. https://www.padtinc.com/2013/08/14/submodeling_ansys_mechanical/.

(5) Submodeling using ansys_workbench_v12 | PPT - SlideShare. https://bing.com/search?q=submodeling+in+Ansys+Workbench.

(6) Submodelling in Ansys - Mechead.com. https://www.mechead.com/submodelling-in-ansys/.

(7) Submodeling using ansys_workbench_v12 | PPT - SlideShare. https://www.slideshare.net/sivasankar1977/submodeling-using-ansysworkbenchv12.

(8) https://bit.ly/3Eo8esU.

(9) https://bit.ly/32eEcuR.

(10) https://bit.ly/3qsytK2.

(11) https://bit.ly/3Bbaaow.

Wednesday, September 20, 2023

💥💥💥 How to define Thermal Contact Conductance in Transient Thermal ( Ansys Workbench)

**Thermal contact conductance** is the study of heat conduction between solid or liquid bodies in thermal contact¹. It is a measure of the **thermal conductivity**, or ability to conduct heat, between two bodies in contact¹. The **thermal contact conductance coefficient** is a property indicating the thermal conductivity between two bodies in contact¹. The inverse of this property is termed **thermal contact resistance**¹.

When two solid bodies come in contact, such as A and B in Figure 1, heat flows from the hotter body to the colder body. A temperature drop is observed at the interface between the two surfaces in contact. This phenomenon is said to be a result of a thermal contact resistance existing between the contacting surfaces¹. Thermal contact resistance is defined as the ratio between this temperature drop and the average heat flow across the interface¹.

Most experimentally determined values of the thermal contact resistance fall between **0.000005 and 0.0005 m²K/W** (the corresponding range of thermal contact conductance is **200,000 to 2000 W/m²K**). The significance of thermal contact resistance depends on the thermal resistances of the layers compared to typical values of thermal contact resistance. It is significant and may dominate for good heat conductors such as metals but can be neglected for poor heat conductors such as insulators¹.

Thermal contact conductance is an important factor in various applications, including electronics, electronic packaging, heat sinks, brackets, industry, nuclear reactor cooling, gas turbine cooling, internal combustion engines, heat exchangers, thermal insulation, press hardening of automotive steels, hypersonic flight vehicles, thermal supervision for space vehicles, and residential/building science¹.

Please note that thermal contact resistance arises due to improper contact between two bodies due to irregularities like scratches, ruptures, or dirt on the surface, which causes less contact area available for heat conduction².

Source:

(1) Thermal contact conductance - Wikipedia. https://en.wikipedia.org/wiki/Thermal_contact_conductance.

(2) Thermal contact resistance: Definition, Formula (Heat transfer). https://mechcontent.com/contact-resistance-heat-transfer/.

(3) Thermal Contact Resistance | Neutrium. https://neutrium.net/heat-transfer/thermal-contact-resistance/.

(4) What is Thermal Contact Resistance - Thermal Engineering. https://www.thermal-engineering.org/what-is-thermal-contact-resistance-thermal-contact-conductance-definition/.

How to define Thermal contact resistance in Transient Thermal Ansys Workbench ?

**Thermal contact resistance** is created by the air gap between the contacting surfaces². It depends on surface roughness, how much pressure is applied on the surfaces in contact, and the kind of thermal paste used to fill up the air gap².

In **Transient Thermal Ansys Workbench**, you can define thermal contact resistance by specifying the **thermal contact conductance coefficient**¹. The inverse of thermal contact conductance is thermal contact resistance¹. The thermal contact conductance coefficient quantifies a contact's ability to conduct heat¹. It is used to calculate the amount of heat transferred through conduction between two bodies in contact¹.

To define thermal contact resistance in Transient Thermal Ansys Workbench, you can follow these steps:

1. Open your Transient Thermal Ansys Workbench project.

2. Select the surfaces that are in contact and for which you want to define thermal contact resistance.

3. Right-click on the selected surfaces and choose "Properties" or "Contact Properties".

4. In the properties window, look for the option to define thermal contact conductance or thermal contact resistance.

5. Enter the desired value for thermal contact conductance coefficient or thermal contact resistance.

6. Save the changes and run the simulation.

Please note that the specific steps may vary depending on the version of Ansys Workbench you are using. It is recommended to refer to the official documentation or user guide for detailed instructions specific to your version of Ansys Workbench.

I hope this helps! Let me know if you have any further questions.

Source:

(1) Thermal contact resistance - Ansys Learning Forum. https://forum.ansys.com/forums/topic/thermal-contact-resistance/.

(2) Thermal Contact Conductance - ANSYS Innovation Courses. https://courses.ansys.com/wp-content/uploads/2020/03/Lesson-3-Thermal-contact.pdf.

(3) Intro to Transient Thermal Analysis - ANSYS Innovation Courses. https://courses.ansys.com/wp-content/uploads/2020/05/Lesson-1-Introduction-to-transient-analysis.pdf.

(4)https://www.engineersedge.com/heat_transfer/thermal_contact_conductance_13849.htm.

To calculate the contact thermal conductance between two steel plates, you need to know the following parameters:

- The thermal conductivity of the steel plates, denoted by k (W/m•K).

- The thickness of each steel plate, denoted by L (m).

- The contact area between the plates, denoted by A (m2).

- The contact pressure between the plates, denoted by P (MPa).

- The surface roughness of the plates, denoted by R (μm).

- The interface fluid between the plates, such as air or oil.

The contact thermal conductance, denoted by h (W/m2K), is a measure of how well heat is transferred across the interface between the plates. It depends on the factors mentioned above, as well as the temperature of the interface. There is no simple formula for contact thermal conductance, but there are some empirical correlations that can be used to estimate it. One such correlation is given by Yovanovich (1981) as:

This correlation is valid for steel plates with surface roughness between 0.1 and 10 μm, contact pressure between 0.1 and 10 MPa, and interface temperature between 20 and 200 °C. It assumes that the interface fluid is air with a thermal conductivity of 0.026 W/m•K.

To use this correlation, you need to plug in the values of k, L, P, R and h into the equation and solve for h. Alternatively, you can use an online calculator such as this one to compute h for you.

I hope this helps you understand how to calculate contact thermal conductance between two steel plates. If you have any further questions, please feel free to ask me. 😊

💥💥💥 What is effective medium theory (EMT) ? Is this model available in Ansys Workbench?

Effective medium theory (EMT) for thermal conductivity is a method to estimate the effective thermal conductivity of a composite material that consists of two or more phases with different properties1. EMT can be used to model the thermal conductivity of materials that have anisotropic or heterogeneous structures, such as coiled aluminum sheets2.

The basic idea of EMT is to replace the composite material with a homogeneous medium that has the same macroscopic behavior as the original material. The effective thermal conductivity of the homogeneous medium is calculated by averaging the thermal conductivities and volume fractions of the constituent phases, taking into account the shape, size, orientation, and distribution of the phases. There are many different EMT models, each with different assumptions and approximations. Some of the most common EMT models are:

- Maxwell model: This model assumes that one phase is dispersed as spherical inclusions in another phase, and that there is no interfacial thermal resistance between the phases3.

- Bruggeman model: This model assumes that both phases are randomly distributed in a symmetric way, and that there is no interfacial thermal resistance between the phases4.

- Maxwell-Garnett model: This model assumes that one phase is dispersed as ellipsoidal inclusions in another phase, and that there is no interfacial thermal resistance between the phases5.

- Hasselman-Johnson model: This model modifies the Maxwell model by introducing an interfacial thermal resistance between the phases.

- Maxwell model: This model is available in the Engineering Data Sources panel under the Effective Medium Theory option1.

- Bruggeman model: This model is available in the Fluent module under the Materials panel as a User-Defined Function (UDF) option2.

- Maxwell-Garnett model: This model is not directly available in Ansys Workbench, but it can be implemented using a UDF or an External Model component34.

- Hasselman-Johnson model: This model is not directly available in Ansys Workbench, but it can be implemented using a UDF or an External Model component34.

1: Missing FE modeler in Ansys Tool box - Ansys Learning Forum 2: Effective medium theory for thermal conductivity of coiled aluminum sheet 3: Importing FE Model in ANSYS Workbench - Eng-Tips 4: Worksheet Option in Ansys Workbench - Skill-Lync

The Maxwell model is a type of effective medium theory (EMT) that can be used to estimate the effective thermal conductivity of a composite material that consists of two phases with different properties1. To define the Maxwell model in Ansys Workbench, you need to do the following steps:

- Go to START > Ansys Em Suite 202x Rx > Modify integration with Ansys (run as admin) and integrate it with workbench2.

- Launch Workbench. You will see Maxwell and other Electronics solvers in the analysis system2.

- Drag and drop Maxwell into the workspace and then import your Maxwell project into it2.

- Select Thermal Conductivity as the property to define and choose Anisotropic for the type3.

- Enter the values of the thermal conductivity tensor components for the composite material. You can use the formula given in this document to calculate these values based on the properties of the phases and their volume fractions1.

The Bruggeman model is a type of effective medium theory (EMT) that can be used to estimate the effective thermal conductivity of a composite material that consists of two or more phases with different properties1. To define the Bruggeman model in Ansys Workbench, you need to do the following steps:

- Go to the Fluent module in the Analysis System and double-click Setup2.

- In the Fluent Launcher panel, select Double Precision and User-Defined Functions (UDF) options and press OK2.

- In the Fluent Text User Interface (TUI), type the following command to load the UDF library that contains the Bruggeman model: /define/user-defined/user-defined-functions/load [library-name] [library-path] where [library-name] is the name of the UDF library and [library-path] is the location of the UDF library on your computer2.

- In the Fluent GUI, go to Materials and select the composite material that you want to define. Under Thermal Conductivity, select User-Defined and choose the Bruggeman model from the drop-down list2.

- Enter the values of the thermal conductivity and volume fraction for each phase of the composite material. You can use the formula given in this document to calculate these values based on the properties of the phases1.

1: Effective medium approximations - Wikipedia 2: Parameter model in Fluent and Workbench - Ansys Learning Forum 3: Effective medium theory for thermal conductivity of coiled aluminum sheet

Sunday, August 20, 2023

Cooling process of the gear on Transient Thermal (Ansys Workbench)

Transient Thermal module is a type of analysis that allows you to simulate the temperature changes and heat transfer in a system over time. It is useful for studying problems that involve time-dependent thermal loads, such as heat treatment, electronic cooling, engine heating, etc.

In Transient Thermal module, you need to specify the initial temperature distribution, the material properties (such as density, specific heat, and thermal conductivity), the boundary conditions (such as convection, radiation, and heat flux), and the time steps for the analysis. The module will solve the heat conduction equation for each time step and generate the results for the temperature, heat flux, heat transfer coefficient, etc.

You can also use Transient Thermal module to perform coupled thermal-structural analysis, where the thermal results are transferred to a structural analysis to calculate the thermal stresses and strains. This can help you evaluate the effects of thermal expansion, contraction, and deformation on your system.

If you want to learn more about Transient Thermal module in Ansys workbench, you can check out some of these resources:

- [Intro to Transient Thermal Analysis - ANSYS Innovation Courses](^5^): This is a PDF document that introduces the basics of transient thermal analysis and the governing equation.

- [Transient Thermal Analysis in ANSYS](^1^): This is a YouTube video that shows you how to do a transient thermal analysis in Ansys workbench with an example problem.

- [Transient heat transfer analysis using ANSYS workbench](^2^): This is another YouTube video that demonstrates how to perform transient heat transfer analysis using Ansys workbench with a different example problem.

I hope this helps you understand what is Transient Thermal module in Ansys workbench.

Source:

(1) Intro to Transient Thermal Analysis - ANSYS Innovation Courses. https://courses.ansys.com/wp-content/uploads/2020/05/Lesson-1-Introduction-to-transient-analysis.pdf.

(2) Transient Thermal Analysis in ANSYS - YouTube. https://www.youtube.com/watch?v=4Jj0s-DAvfg.

(3) Transient heat transfer analysis using ANSYS workbench. https://www.youtube.com/watch?v=wJW6IIovyPo.

(4) ANSYS Transient Thermal Tutorial - Convection of a Bar in Air. https://www.youtube.com/watch?v=fd0xQQ1IGvw.

(5) Setup Transient Thermal Analysis - ANSYS Innovation Courses. https://courses.ansys.com/index.php/courses/radiation-between-surfaces/lessons/physics-setup-lesson-5-16/topic/setup-transient-thermal-analysis/.

Friday, August 11, 2023

Types of supports and examples - Ansys Static Structural

Supports are used to represent parts that are not present in the model but are interacting with it. Supports help truncate the domain, which helps in efficiently obtaining numerically accurate results without modeling parts of the geometry that are not of primary interest. There are different types of support available, among which you need to choose the appropriate one for your analysis. Here are some of the common types of supports and their explanations:

- **Fixed Support**: This type of support constrains all the degrees of freedom of the selected entity (body, face, or edge). It means that the entity cannot move or rotate in any direction. Fixed support is equivalent to applying zero displacement to all directions. Fixed support is useful for modeling rigid connections or supports that do not allow any movement. For example, you can use fixed support to model a bolted joint or a clamped beam.

- **Displacement Support**: This type of support specifies a zero or non-zero displacement to any of the three orthogonal directions (X, Y, Z) of the selected entity. It means that the entity can move only in the specified direction and amount, while being constrained in the other directions. Displacement support is useful for modeling prescribed displacements or deformations that are known in advance. For example, you can use displacement support to model a spring or a thermal expansion.

- **Frictionless Support**: This type of support constrains translational movement in the direction normal to the surface of the selected entity (face or edge). It means that the entity can slide freely along the surface, but cannot separate from it or penetrate into it. Frictionless support is useful for modeling smooth contact surfaces or supports that do not resist tangential forces. For example, you can use frictionless support to model a roller or a slider.

- **Cylindrical Support**: This type of support constrains translational movement in two directions (radial and axial) and rotational movement in one direction (circumferential) of the selected entity (face or edge). It means that the entity can rotate freely around an axis, but cannot move along or away from it. Cylindrical support is useful for modeling cylindrical or circular surfaces or supports that allow rotation but not translation. For example, you can use cylindrical support to model a pin or a hinge.

- **Compression Only Support**: This type of support constrains translational movement in the direction normal to the surface of the selected entity (face or edge) only when it is in compression. It means that the entity can separate from the surface when it is in tension, but cannot penetrate into it when it is in compression. Compression only support is useful for modeling contact surfaces or supports that do not resist tensile forces. For example, you can use compression only support to model a foundation or a soil.

- **Elastic Support**: This type of support applies a linear elastic spring or damper to the selected entity (body, face, or edge). It means that the entity can move or rotate in any direction, but with a resistance proportional to its stiffness or damping coefficient. Elastic support is useful for modeling flexible connections or supports that have some degree of compliance. For example, you can use elastic support to model a rubber bushing or a shock absorber.

- **Remote Displacement Support**: This type of support applies a displacement to a remote location and transfers it to the selected entity (body, face, or edge) through rigid links. It means that the entity can move or rotate in any direction as specified by the remote displacement, while being rigidly connected to the remote location. Remote displacement support is useful for modeling complex loading conditions or supports that are far away from the model. For example, you can use remote displacement support to model a wind load or a seismic load.

I hope this helps you understand the types of supports in Ansys Static Structural. If you want more details or examples, you can check out these sources below. If you have any other questions, feel free to ask me 😊.

Source:

(1) Types of Supports in Static Structural Analysis. https://www.graspengineering.com/types-of-supports-in-static-structural-analysis/.

(2) Types of Supports in Static Structural Analysis. https://www.graspengineering.com/types-of-supports-in-static-structural-analysis/.

(3) Determining which Support to Use - ANSYS Innovation Courses. https://courses.ansys.com/index.php/courses/structural-boundary-conditions/lessons/determining-which-support-to-use-lesson-1/.

(4) Determining which Support to Use - ANSYS Innovation Courses. https://courses.ansys.com/index.php/courses/structural-boundary-conditions/lessons/determining-which-support-to-use-lesson-1/.

(5) Boundary Conditions and Explanations in ANSYS - Mechead.com. https://www.mechead.com/boundary-conditions-and-explanations-in-ansys/.

(6) Boundary Conditions and Explanations in ANSYS - Mechead.com. https://www.mechead.com/boundary-conditions-and-explanations-in-ansys/.

(7) Defining Elastic Supports In ANSYS Mechanical Analyses - ML. https://mechanicalland.com/defining-elastic-supports-in-ansys-mechanical-analyses/.

(8) Defining Elastic Supports In ANSYS Mechanical Analyses - ML. https://mechanicalland.com/defining-elastic-supports-in-ansys-mechanical-analyses/.

How to use these supports from Ansys Static Structural. Here are some scenarios that illustrate the application of different types of supports:

- Fixed Support: Suppose you want to model a cantilever beam that is fixed at one end and has a point load at the other end. You can use a fixed support to constrain all the degrees of freedom of the face where the beam is attached to the wall. This will prevent the beam from moving or rotating in any direction. You can then apply a force load to the face where the point load is acting. The screenshot below shows how to apply a fixed support in Ansys Workbench¹.

- Displacement Support: Suppose you want to model a spring that is stretched by a known amount. You can use a displacement support to specify a non-zero displacement in the direction of stretching for the face where the spring is attached to a rigid body. This will allow the spring to deform in that direction, while being constrained in the other directions. You can then apply a fixed support to the other face of the spring to prevent it from moving or rotating. The screenshot below shows how to apply a displacement support in Ansys Workbench².

- Frictionless Support: Suppose you want to model a roller that is resting on a horizontal surface and has a vertical load applied to it. You can use a frictionless support to constrain the translational movement in the normal direction for the face where the roller is in contact with the surface. This will prevent the roller from separating from or penetrating into the surface, while allowing it to slide freely along it. You can then apply a pressure load to the face where the vertical load is acting. The screenshot below shows how to apply a frictionless support in Ansys Workbench³.

- Cylindrical Support: Suppose you want to model a hinge that connects two bars and allows them to rotate around an axis. You can use a cylindrical support to constrain the translational movement in the radial and axial directions and the rotational movement in the circumferential direction for the face where the hinge is attached to one of the bars. This will prevent the bar from moving along or away from the axis, while allowing it to rotate around it. You can then apply a moment load to the other bar to induce rotation. The screenshot below shows how to apply a cylindrical support in Ansys Workbench.

![Cylindrical Support]

- Compression Only Support: Suppose you want to model a column that is supported by a foundation and has an axial load applied to it. You can use a compression only support to constrain the translational movement in the normal direction for the face where the column is in contact with the foundation, only when it is in compression. This will prevent the column from penetrating into the foundation when it is compressed, while allowing it to separate from it when it is in tension. You can then apply a force load to the face where the axial load is acting. The screenshot below shows how to apply a compression only support in Ansys Workbench.

![Compression Only Support]

- Elastic Support: Suppose you want to model a rubber bushing that connects two shafts and has some degree of compliance. You can use an elastic support to apply a linear elastic spring or damper to the face where the bushing is attached to one of the shafts. This will allow the shaft to move or rotate in any direction, but with a resistance proportional to its stiffness or damping coefficient. You can then apply a torque load to the other shaft to induce rotation. The screenshot below shows how to apply an elastic support in Ansys Workbench.

![Elastic Support]

- Remote Displacement Support: Suppose you want to model a wind turbine blade that is subjected to a wind load that varies along its length. You can use a remote displacement support to apply a displacement to a remote location and transfer it to the face where the blade is attached to the hub through rigid links. This will allow the blade to move or rotate in any direction as specified by the remote displacement, while being rigidly connected to the remote location. You can then define a table or function for the remote displacement that represents the wind load profile. The screenshot below shows how to apply a remote displacement support in Ansys Workbench.

![Remote Displacement Support]

I hope these examples help you understand how to use these supports from Ansys Static Structural. If you want more details or examples, you can check out these sources: [Types of Supports in Static Structural Analysis](^2^) ², [Types of Supports in Structural Analysis - YouTube](^3^) ³, [Lecture 7 Static Structural Analysis - Rice University](^1^) ¹, and [Defining Elastic Supports In ANSYS Mechanical Analyses - ML] . If you have any other questions, feel free to ask me 😊.

Source:

(1) Lecture 7 Static Structural Analysis - Rice University. https://www.clear.rice.edu/mech517/WB16/lectures_trainee/Mechanical_Intro_16.0_L07_Static.pdf.

(2) Lecture 7 Static Structural Analysis - Rice University. https://www.clear.rice.edu/mech517/WB16/lectures_trainee/Mechanical_Intro_16.0_L07_Static.pdf.

(3) Types of Supports in Static Structural Analysis. https://www.graspengineering.com/types-of-supports-in-static-structural-analysis/.

(4) Types of Supports in Static Structural Analysis. https://www.graspengineering.com/types-of-supports-in-static-structural-analysis/.

(5) Types of Supports in Structural Analysis - YouTube. https://www.youtube.com/watch?v=yiBn0iaV4z0.

(6) Types of Supports in Structural Analysis - YouTube. https://www.youtube.com/watch?v=yiBn0iaV4z0.

(7) Types of Supports in Static Structural Analysis. https://www.graspengineering.com/types-of-supports-in-static-structural-analysis/.

(8) Types of Supports in Structural Analysis - YouTube. https://www.youtube.com/watch?v=yiBn0iaV4z0.

(9) Lecture 7 Static Structural Analysis - Rice University. https://www.clear.rice.edu/mech517/WB16/lectures_trainee/Mechanical_Intro_16.0_L07_Static.pdf.

If U want to learn more about ansys check links below

How to deal with peak stresses on Ansys Structural (Mechanical)

How to prepare strength (Structural) and cfd analysis in Ansys Mechanical - Rotating Elements

How to... fix "gui-domain-label: no domain selected" in Ansys Fluent and MEMERR in CFX

Saturday, June 25, 2022

Wpływ różnych kierunków przewodnictwa cieplnego materiałów na rozkład temperatury - Ansys Transient Thermal (Mechanical) część 1

Friday, June 24, 2022

Jak zdefiniować materiał anizotropowy w module Transient Thermal Ansys

W kolejnym wpisie chciałbym pokazać jak zdefiniować materiał anizotropowy w Transient Thermal. W kilku prostych krokach jesteś w stanie zdefiniować ortotropię materiału w funkcji temperatury dla każdego kierunku przewodnictwa.

|

| Jak zdefiniować różne przewodnictwo dla każdego kierunku materiału? |

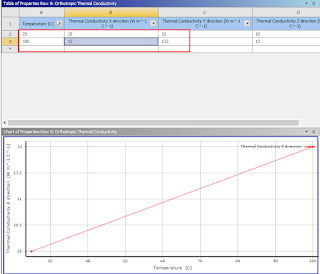

W pierwszym kroku musimy wprowadzić dane do Engineering Data na schemacie blokowym Ansys Workbench. Następnie przeciągamy funkcje ortotropowej przewodności cieplnej z przybornika po lewej stronie do właściwości materiału poniżej izotropowej przewodności termicznej. Po wykonaniu tej czynności nasz parametr izotropowej przewodności cieplnej zostanie przekreślony i nieważny (nie jest uwzględniony w obliczeniach). Następnie możemy przejść do definicji materiału anizotropowego.

|

| Jak zdefiniować ortotropowe właściwości przewodnictwa cieplnego w programie Ansys Workbench? |

Po kliknięciu na Orthotropic Thermal Conductivity (czerwona ramka) pojawi się tabela, w której definiujemy właściwości przewodnictwa materiału (pomarańczowa ramka). Definiujemy przewodnictwo wzdłuż każdej osi układu współrzędnych. Dlatego ważne jest, aby nasz model geometryczny był dobrze zorientowany w przestrzeni 3d zgodnie z osiami. Jeśli nie jest dobrze zorientowany, należy go przenieść do początku układu współrzędnych za pomocą opcji translacji.

|

| Jak zdefiniować przewodność ortotropową w zależności od temperatury? |

Wednesday, December 8, 2021

Investigation of the influence of conductivity of two-component geometry in Ansys Transient Thermal PART 4 ORTHOTROPIC

Sunday, November 21, 2021

Investigation of the influence of conductivity of two-component geometry in Ansys Transient Thermal PART 3

In this post, we compare the heat conduction dynamics of geometry from the previous postss in two directions: longitudinal and transverse. Of course, all boundary conditions, or more precisely, their value, remain unchanged. The only variable will be the modification of their position.

|

| Transverse or Longitudinal - which conduction is more dynamic ? |

Investigation of the influence of conductivity of two-component geometry in Ansys Transient Thermal PART 2

Investigation of the influence of conductivity of two-component geometry in Ansys Transient Thermal PART 1

Wednesday, September 15, 2021

How to... use GPU on Transient / Static Thermal Ansys Workbench

Nowadays, most of the complicated CAE calculations and deep learning are done with the GPU. In Ansys software it is possible to use the computing power of graphic cards in Fluent and Ansys Mechanical. In this post I will show you how to enable GPU acceleration in Transient and Static Thermal.

|

| How to use GPU in Ansys Mechanical |

Monday, August 2, 2021

Transient Thermal good way to make quick cfd/thermal calculations

Some engineers unfamiliar with the most famous CFD programs such as Fluent, CFX or Open Foam may have problems solving technical issues related to heat transfer.

Saturday, July 17, 2021

How to... define quasi porous material in Transient Thermal (material combination)

A very interesting option in newer versions of Ansys Workbench is defining materials consisting of several components. It is especially useful because the program automatically updates the physical and thermal properties of the new defined mixture. It is possible to create, for example, porous materials consisting of a solid and a fluid.

Wednesday, July 14, 2021

How to... simplify case when Your Fluent Structural FSI doesn't work ?

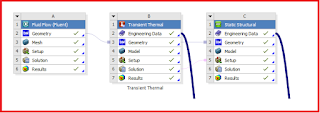

It often happens that we want to do a coupled analysis consisting of two CFD and Structural modules. The purpose of FSI analyzes is to set the thermal conditions that came out from CFD simulation to the Structural analysis as boundary conditions. In the module for mechanical calculations itself, we cannot set a heterogeneous temperature profile, therefore it is necessary to perform two analyzes in these cases as FSI. A very common problem in this type of analysis is a bad transfer of thermal conditions to the Structural module. The distribution of values is not the same as what we came out with CFD. Therefore, in these cases, you can simplify the analysis by adding one more Transient Thermal module from which the transfer of temperature distributions is burdened with a much smaller error.

|

| III stages for simplify FSI case |

Popular posts

-

Calculating the Oscillatory Shear Index (OSI), Ig factor, Area Averaged Wall Shear Stress (AAWSS), and Time Averaged Wall Shear Stress (TAWS...

-

The error message you're encountering in Ansys Electronics Desktop The quality of some mesh elements is not acceptable for solution. Pl...

-

You can potentially model the membrane in your water treatment scheme using the porous media option available in Ansys Fluent, but with som...

-

In today's post, we will deal with another error that may occur during the analysis. The error that is described below concerns Fluent a...

-

There are several methods of modeling the closed gas cycle in Ansys Fluent, depending on the type of problem, the assumptions, and the desi...

-

OptiSLang is a software tool that enables you to perform sensitivity analysis, optimization, and robustness evaluation of your simulation m...

-

1. Multiphase Configuration and Failure: Fluent's Alkaline Electrolysis module assumes a specific multiphase configuration with water ...