Species model in Ansys Fluent is a feature that allows you to model the mixing and transport of chemical species by solving conservation equations describing convection, diffusion, and reaction sources for each component species¹. You can use this model to simulate non-reacting or reacting flows, with reactions occurring in the bulk phase, on wall or particle surfaces, or in the porous region². You can also choose different reaction mechanisms and rate formulations to suit your problem³.

Some examples of applications that use species model in Ansys Fluent are:

- Combustion modeling using finite-rate chemistry²

- Chemical vapor deposition (CVD) processes²

- Fuel cell modeling

- Electrochemical reactions

Source:

(1) ANSYS FLUENT 12.0 User's Guide - 33.3.17 Species Model Dialog Box - ENEA. https://www.afs.enea.it/project/neptunius/docs/fluent/html/ug/node1036.htm.

(2) ANSYS FLUENT 12.0 User's Guide - 15. Modeling Species Transport and .... https://www.afs.enea.it/project/neptunius/docs/fluent/html/ug/node512.htm.

(3) ANSYS FLUENT 12.0 Theory Guide - 7. Species Transport and Finite ... - ENEA. https://www.afs.enea.it/project/neptunius/docs/fluent/html/th/node126.htm.

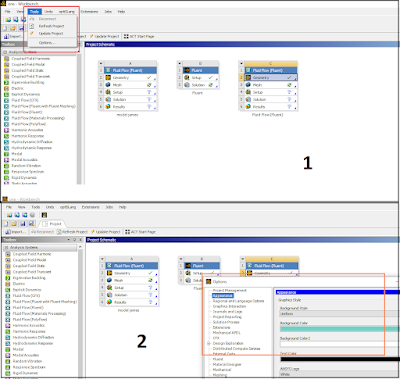

How to define species model in Ansys ?

To model species transport and finite-rate chemistry in Ansys Fluent, you need to follow these steps:

- Enable the **Species Transport** model in the **Species Model** dialog box. You can also choose the **Non-Premixed Combustion** model if you want to simulate turbulent reacting flow using the non-premixed combustion model¹.

- Define the **species** that are involved in your problem. You can add or remove species from the list of available species in the **Boundary Species** section of the **Species Model** dialog box¹.

- Define the **reactions** that occur in your problem. You can choose from different reaction mechanisms and rate formulations in the **Reactions** section of the **Species Model** dialog box¹. You can also specify the **reaction zones**, where the reactions take place, and the **reaction orders**, which determine how the reaction rates depend on the species concentrations².

- Define the **boundary conditions** for your problem. You can specify the **species mass fractions**, **temperature**, and **reaction rates** at the inlet, outlet, wall, or other boundaries².

- Initialize and run the calculation. You can monitor the **species mass fractions**, **temperature**, and **reaction rates** during the solution process².

Source:

(1) ANSYS FLUENT 12.0 User's Guide - 33.3.17 Species Model Dialog Box - ENEA. https://www.afs.enea.it/project/neptunius/docs/fluent/html/ug/node1036.htm.

(2) 15. Modeling Species Transport and Finite-Rate Chemistry - ENEA. https://www.afs.enea.it/project/neptunius/docs/fluent/html/ug/node512.htm.

(3) 15. Modeling Species Transport and Finite-Rate Chemistry - ENEA. https://www.afs.enea.it/project/neptunius/docs/fluent/html/ug/node512.htm.

(4) #Ansys Fluent Tutorial | Modeling Species Transport and Gaseous .... https://www.youtube.com/watch?v=HcX1t9EDpSs.

What are differences between species model and Euler model in Ansys Fluent

The species model and the Euler model are two different approaches for modeling multiphase flows in Ansys Fluent. The species model is used to model the mixing and transport of chemical species by solving conservation equations describing convection, diffusion, and reaction sources for each component species³. The Euler model is used to model the interpenetrating continua of different phases by solving a set of momentum and continuity equations for each phase².

Some of the differences between the species model and the Euler model are:

- The species model is suitable for non-reacting or reacting flows, with reactions occurring in the bulk phase, on wall or particle surfaces, or in the porous region³. The Euler model is suitable for granular (fluid-solid) flows or nongranular (fluid-fluid) flows, with coupling achieved through the pressure and interphase exchange coefficients².

- The species model shares a single set of momentum equations by the fluids, and tracks the volume fraction of each of the fluids in each computational cell³. The Euler model solves a separate set of momentum equations for each phase, and accounts for the phasic volume fractions that sum up to one².

- The species model requires the definition of species, reactions, reaction zones, and reaction orders³. The Euler model requires the definition of interphase drag, lift, wall lubrication, turbulent dispersion, and virtual mass forces².

Source:

(1) ANSYS FLUENT 12.0 User's Guide - 15. Modeling Species Transport ... - ENEA. https://www.afs.enea.it/project/neptunius/docs/fluent/html/ug/node512.htm.

(2) ANSYS FLUENT 12.0 Theory Guide - 16.2.1 Approaches to Multiphase Modeling. https://www.afs.enea.it/project/neptunius/docs/fluent/html/th/node293.htm.

(3) ANSYS FLUENT 12.0 User's Guide - 33.3.17 Species Model Dialog Box - ENEA. https://www.afs.enea.it/project/neptunius/docs/fluent/html/ug/node1036.htm.